DH31-EX

High strength, tough and high heat check resistance hot work die steel.

OVERVIEW

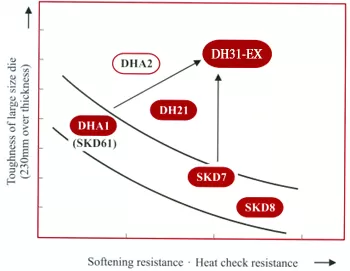

DH31-EX is a hot working die steel with the best balance of strength and toughness showing the comparable softening resistance to SKD7 and twice hardenability as that of SKD61.

Applications include:

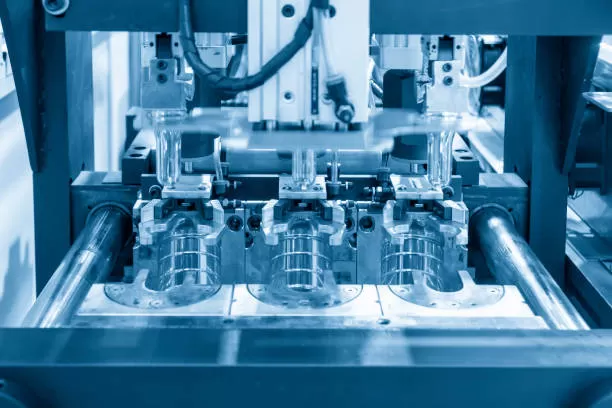

Aluminum Die Cast Dies

Aluminum Die Cast Parts

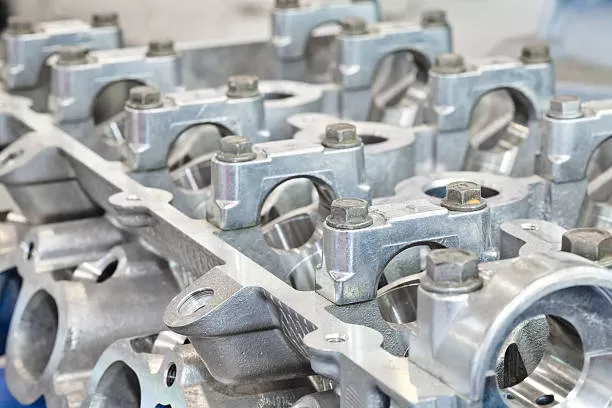

Hot Forging Dies

Hot Pressing Dies

Aluminum Extrusion Dies

UNIQUE CHARACTERISTICS

- High hardenability. High toughness is obtained even in large size die.

- High strength. High softening resistance at elevated temperature contributes to high wear resistance.

- High toughness. DH31-EX has higher toughness than that of SKD61.

- High heat check resistance. Excellent heat check resistance leads to longer life.

PRODUCT BROCHURE

These properties are obtained through its chemistry as well as its unique manufacturing processes of ladle refinement, vacuum degassing and forging methods. DC53 also has excellent machining characteristics and is well suited as a sub-straight for PVD surface treatments. DC53 can also be hot process CVD and TD (Thermal Diffusion) coated however post heat treat is generally recommended.

CHEMICAL COMPOSITION

PHYSICAL PROPERTIES

Coefficient of thermal expansion

Specific heat

Thermal conductivity

Density

Characteristics

Tempering hardness

- Quenching temp: 1030°C

- T.P. size: 10H x 10W x 15L

Softening resistance

- Holding temp.: 600°C

- Quenching temp: 1030°C x 30min. –> 150 Dia. Bar, AC

- T.P. size: 10H x 10W x 15L

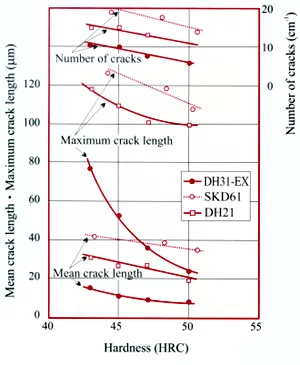

Heat check resistance

Heat check resistance is further improved by increasing hardness without deteriorating toughness.

An example to improve heat check resistance (200mmm thickness air cool quenched die)

<Test procedures>

- Specimen: 15mm

- I/Heating: 20<-> 700C

- Number of cycles: 1000 times

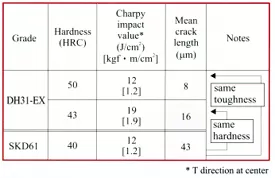

Toughness

- Quenching temp: 1030°C x 30min. –> 150 Dia. Bar, AC

- T.P. size: L

Elevated temperature tensile properties

- T.P. size: Ø 8 x 40L

Erosion resistance

Creep properties

Hardenability

Continuous cooling transformation curve

Bainite hardenability

Quenching cooling time vs. toughness

Cooling time of mid portion from 1030°C to 300°C (min)

TP size: Ø440

Quenching temp: 1030°C

Surface Hardening Properties

PS, PW process

- Daido Amistar’s originally developed process.

- PW process improves wear, fatigue and corrosion resistance.

- PS process improves scuffing and erosion resistance.

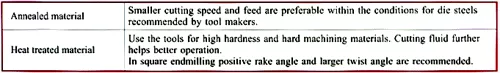

MACHINABILITY

- DH31-EX shows good machinability as high strength-high tough grades.

- Recommended machining conditions

REPAIR WELDING CONDITIONS

- TIG manual welding condition