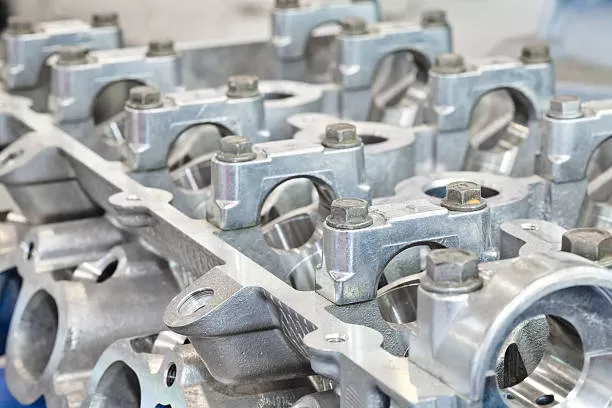

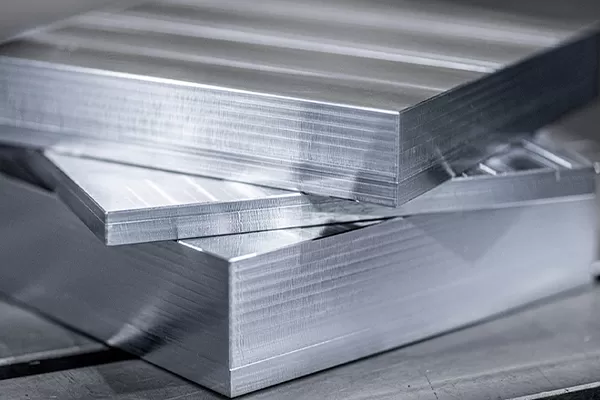

PLASTIC & RUBBER MOLD STEELS

OVERVIEW

Our industry leading steels feature uniform hardness and clean microstructures for machining, stability in use, and maintenance resulting in superior plastic and rubber mold.

RECOMMENDED READING

TOOLING: Solutions Start in the Mold

LeVic Plastics overcomes challenges with its approach to tooling, including a creative way to vent using porous mold steel.

What You Should Consider When Purchasing P20 Steel

When buying P20 steels, mold makers should be aware of the variations and key issues that affect delivery, cost, and lead times.

Pre-Hardened Tool Steel Saves Time and Money

Using NAK55 standard mold bases allows mold makers to focus on crucial core and cavity work.

Steel Selection – Closing the Gap with Offshore Tooling

The most discussed topic in the mold-building industry today is cheaper tooling from offshore competition.

High-Performance Mold Steel

In the past 30 years, there have been tremendous improvements in machine and cutting tool technologies. High-speed machining can accomplish cutting speeds and accuracies that toolmakers in the past could only dream of.

DH2F

DH2F is a modified H-13, pre-hardened 37-41 HRC.

Unique Characteristics:

- 38-42 HRc hardness.

- Through hardened for exceptional dimensional stability.

- Cuts mold-making costs by reducing man hours required for machining.

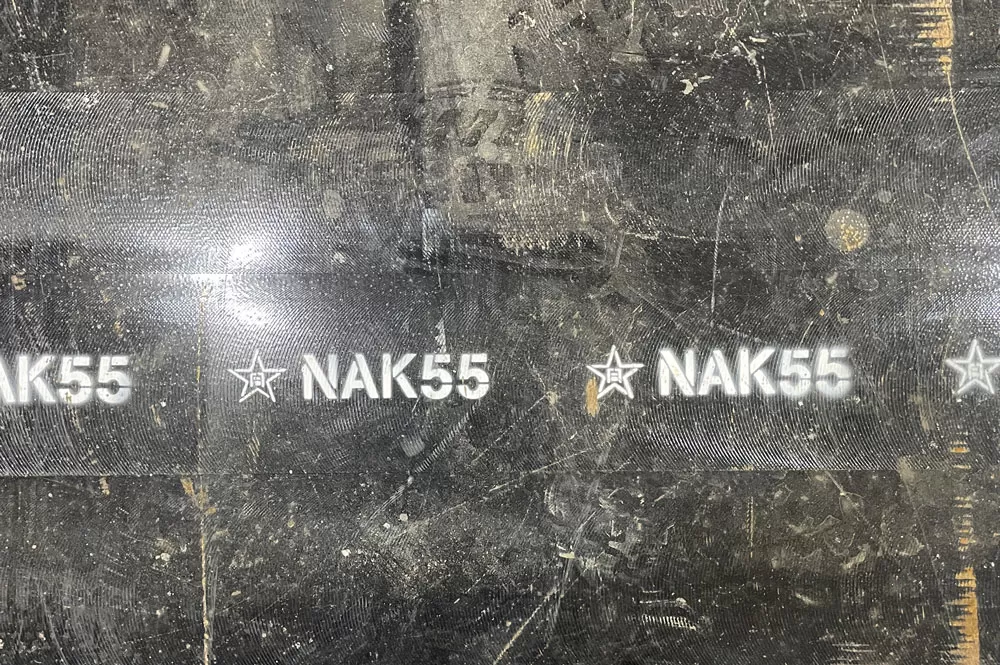

NAK 55

NAK55 is a 40 HRC pre-hardened, high performance, high precision, mold steel.

Unique Characteristics:

- Machines 30- to 40 percent faster than P20

- Pre-hardened to 38-42 HRC

- Uniform microstructure & hardness (40 HRC between surface & interior)

NAK80

NAK80 is a 40 HRC pre-hardened, high performance, high precision, lens-quality mold steel.

Unique Characteristics:

- Machines up to 20 percent faster than 30 HRc P20

- Pre-hardened to 38-42 HRC

- Uniform microstructure & hardness (40 HRC between surface & interior)

PX5

PX5 is a modified P20, high performance, high precision, mold steel.

Unique Characteristics:

- Exceptionally stable steel with clean, uniform microstructure – no pin holes, inclusions or hard spots.

- 29-33 HRC hardness.

- Uniform hardness throughout, even in heavy sections.

S-STAR

420 ESR Stainless Steel

Unique Characteristics:

- Excellent corrosion resistance

- High hardness: maximum 53 HRC is obtained

- Superb mirror-finish surface

SUPERPLAST® STAINLESS

Superplast Stainless is a prehardened, free-machining, stainless mold steel specially designed for plastic mold bases. It also provides improved performances compared to standard grades such as W1.2085.

Superplast Stainless offers Plastic & Rubber molds:

- Improved machinability

- Improved consistency and weldability

Moreover, thanks to its low Carbon and 12% Chromium content, Superplast Stainless ensures good corrosion resistance, both in humid atmospheres and in corrosive molding environments (PVC).

TOOLOX 33

TOOLOX 33 is a quenched and tempered tool steel designed to have low residual stresses and extremely good machinability.

Unique Characteristics:

- Especially suited for plastic molds and rubber molds, having excellent polishing and photoetching ability.

- Supplied in plate thickness 1/2” – 5 1/8”.

- Hardness 30-35 HRC.

TOOLOX 44

TOOLOX 44 is a new quenched and tempered tool steel designed to have high impact and low residual stresses and therefore good dimensional stability.

Unique Characteristics:

- Despite hardness of nominal 45 HRC, this new steel is easy to machine.

- Particularly suitable for manufacturing plastic molds because it can be polished and etched with very good results.

- Great for guide rails, bending tools, etc. when high stability materials are required.