Superplast® Stainless

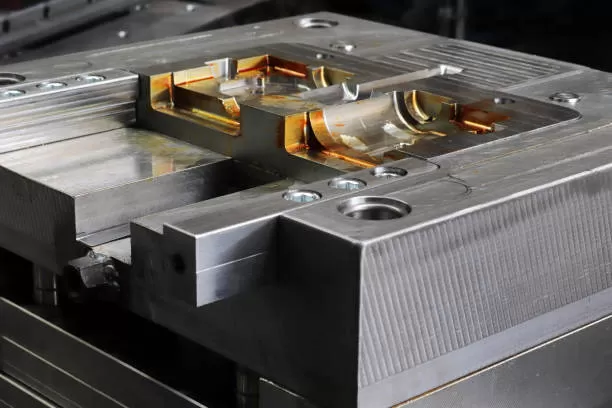

Superplast Stainless is a prehardened, free-machining, stainless mold steel specially designed for plastic mold bases.

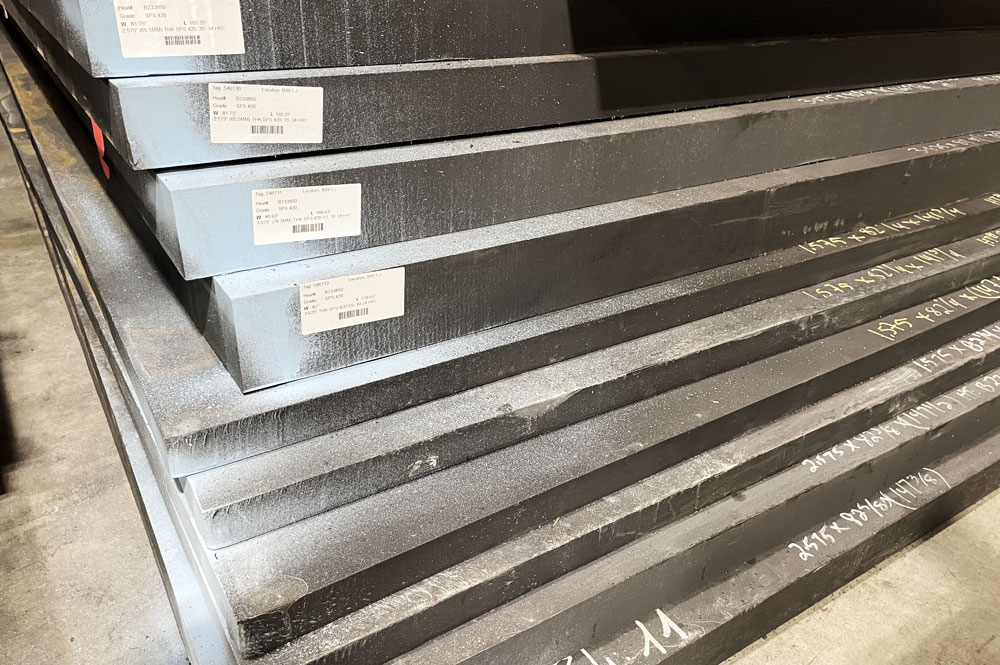

Available in plate up to 5.9 inches.

OVERVIEW

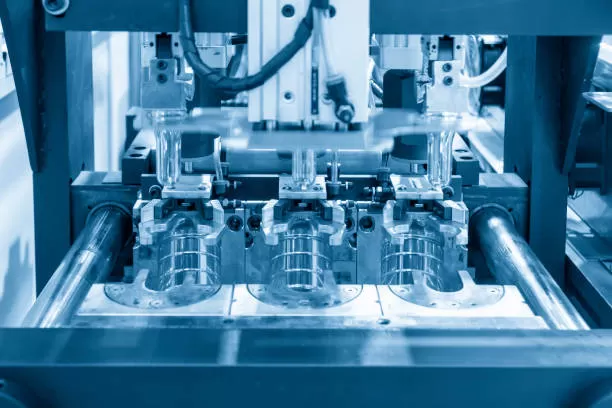

Superplast Stainless is a prehardened, free-machining, stainless mold steel specially designed for plastic mold bases. It also provides improved performances compared to standard grades such as W1.2085.

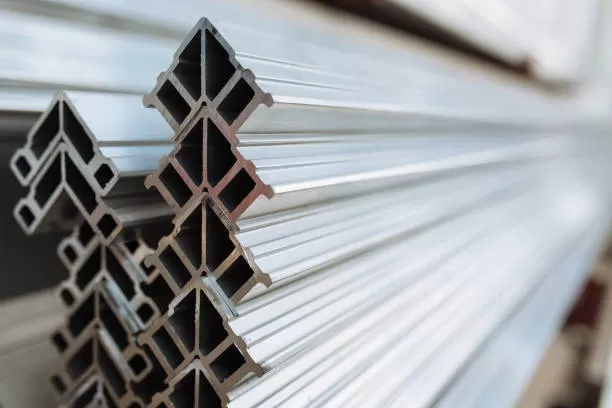

Applications include:

Plastic Molds

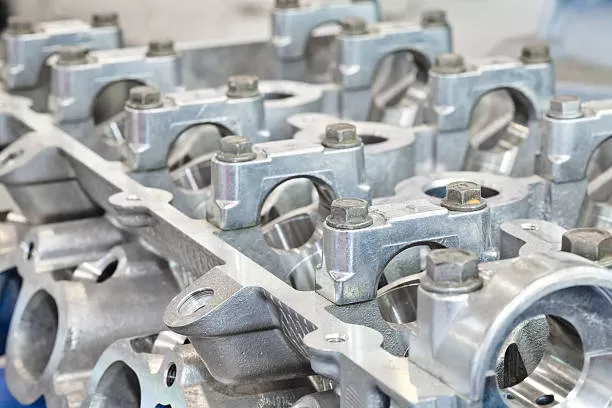

Zinc Diecasting Dies

Short Run Aluminum Diecasting Dies

Plunger Tips & Sprue Bushings

Die Plate Strippers

Dies for Aluminum Extrusions

Patterns & Core Boxes

Others

UNIQUE CHARACTERISTICS

Superplast Stainless offers Plastic & Rubber molds:

- Improved machinability

- Improved consistency and weldability

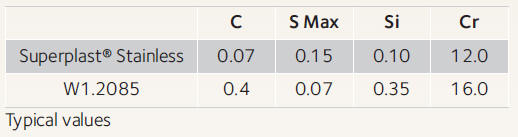

Moreover, thanks to its low Carbon and 12% Chromium content, Superplast Stainless ensures good corrosion resistance, both in humid atmospheres and in corrosive molding environments (PVC).

PRODUCT BROCHURE

CHEMICAL COMPOSITION

With its low Carbon and 12% Chromium content, Superplast Stainless offers excellent corrosion resistance in molding, harsh environments and high humidity conditions.

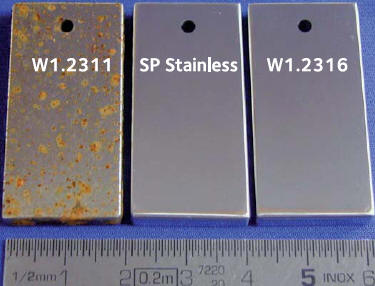

CORROSION RESISTANCE

Thanks to its specific chemistry with a low carbon content, high level of chromium, and other appropriate alloying elements, Superplast Stainless offers good corrosion resistance in corrosive molding environments (PVC) and in humid atmospheres.

Humid-dry alternated atmosphere test.

MACHINABILITY

Stainless. Performances are definitively improved compared to conventional grades.

Machining test parameters

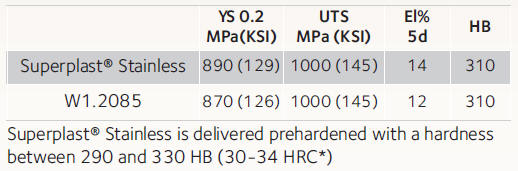

MECHANICAL PROPERTIES

* HRC Hardness is only indicative value (translation from HB according to ISO 18265 : 2003 table B2)

MICROSTRUCTURE

Superplast Stainless is a martensitic stainless steel offering microstructure and hardness consistency through thickness.

Example in a 100 mm (4”) thick plate.

WELDING GUIDELINES

The low carbon content offers a good aptitude for weld repairs, avoiding any risk of cold cracking when appropriate welding wire is used.

To obtain more information regarding welding process, please contact us.